How Premier Aluminum Llc can Save You Time, Stress, and Money.

Table of ContentsThe Main Principles Of Premier Aluminum Llc The smart Trick of Premier Aluminum Llc That Nobody is Talking About8 Simple Techniques For Premier Aluminum LlcFascination About Premier Aluminum LlcGetting My Premier Aluminum Llc To Work

When picking a light weight aluminum shop for your manufacturing needs, it's vital to study several factors. Among one of the most important facets to think about is the experience and proficiency of the shop. Choosing a shop that has the right understanding of the light weight aluminum spreading procedure, and the portfolio to show for it, assists to have an effective outcome for your task.Having the experience and sector expertise to craft your castings for ideal production and top quality results will certainly improve the job. Producing aluminum spreading calls for a facility set of processes to achieve the right outcomes. When choosing a brand-new light weight aluminum shop to companion with, ensure they have extensive market experience and are knowledgeable regarding all facets of the light weight aluminum casting procedure: style, production, material analysis, and item screening.

The factory needs to additionally have a tried and tested track record of delivering remarkable items that satisfy or exceed client expectations. Quality control must additionally be at the top of your checklist when choosing a light weight aluminum shop. By dealing with a qualified shop that follows the standards for quality control, you can shield the integrity of your product and ensure it satisfies your specs.

Some Known Facts About Premier Aluminum Llc.

Various components that very made complex forms can be produced utilizing this procedure. Prior to you begin browsing for a trusted light weight aluminum die wheel, there are some crucial points that you require to do.

You have to ask yourself what kind of aluminum pass away spreadings you require. After identifying what you call for, you have to mention the specs of the light weight aluminum die castings you call for.

Do you understand just how much money you have to invest on the products? In order to do this, the most effective point to do is to figure out the number of aluminum diecasts you require. After having this information, you can start looking into aluminum die-casting manufacturers. You can do this by just keying the key words" Light weight aluminum pass away casting suppliers" on the Google online search engine.

A few of the questions you need to ask yourself are whether they have actually experienced and well-trained drivers, for how long their company has actually functioned, or if they have some success. You can usually get the solutions to these inquiries from the manufacturer's internet site. You can research various other websites or exterior sources to confirm if the details offered on the manufacturer's web site is authentic.

Premier Aluminum Llc Can Be Fun For Everyone

An additional thing you need to think about is the maker's ability to produce aluminum die-casting items. To put it simply, the quantity of products the supplier can create at a given time. Several of the important questions you need to ask on your own are whether the supplier can produce a greater quantity or can the manufacturer fulfill your needs.

(https://premieraluminum.edublogs.org/2024/12/12/top-rated-aluminum-casting-company-why-premier-aluminum-llc-stands-out/)What if your firm calls for 10,000 items of particular device components from the maker within one month? You ordered this quantity; however, the supplier official site can just create 5000 pieces of these device parts within one month (Aluminum Castings). Consequently, you won't have the ability to obtain the quantity that you get promptly

Not known Incorrect Statements About Premier Aluminum Llc

Thus, it is important that you need to inquire if the supplier is carrying out an in-house tooling procedure. In addition, you need to ask the producer how a lot the expense of in-house tooling is. Remember that the in-house tooling procedure, which permits you to produce unique designs and forms can be an additional expense.

This element straight associates with the supplier's manufacturing ability. You need to look for a maker that can ensure quicker delivery of items. Nevertheless, this should be performed in such a means that high-grade criteria are preserved. This can ensure that you can get your products on schedule, and you can prevent missing out on those valuable company opportunities.

This implies that there are numerous options that you can select from. That is why it is substantially recommended that you must pick a producer that can generate different types of light weight aluminum die-cast products.

What Does Premier Aluminum Llc Mean?

A lot of usually, these light weight aluminum die-casting products will need some decorations, machining, or completing touches. Having this in mind, you need to look for a manufacturer that can execute a variety of second ending up works when die spreading is done. Some examples of ending up operations consist of Chromating, CNC Machining, Sandblasting, Powder layer, Anodized, E-coating, Damp paint, Plating, and several even more.

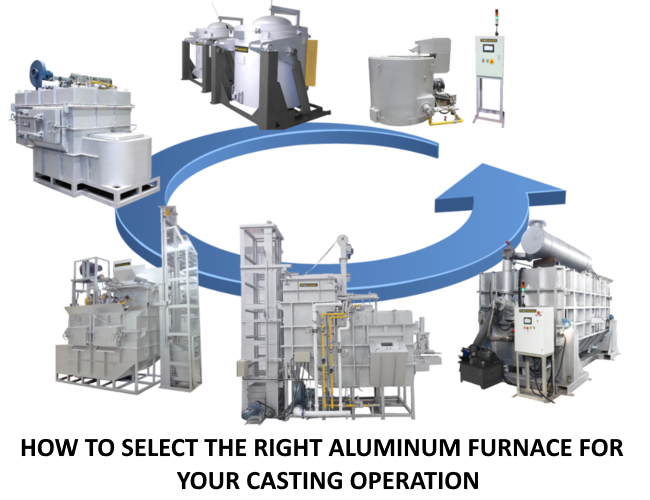

Die casting is one of the most cost-efficient, precise, and protean production processes in the globe minute. The process includes fitting molten significance, under pressure, right into a suitable die (planet), and previously solidified it can be expelled and ended up (if essential) in a range of methods.